The Importance of Buffing Pad Diameter.

When it comes to polishing paint, buffing pads are as critical to polishing performance as tires are to over-the-road transportation vehicles. Choosing the ideal buffing pad can be frustrating, as there are a multitude of designs, sizes, and materials available. Regardless the type of pad you end up choosing, you’ll also have to decide on its diameter. A simple choice? Perhaps. But make no mistake: pad diameter is SO important to polishing performance.

Buffing Pad Parameters.

Imagine attempting to choose a buffing pad for the first time: would you opt for a pad that is rigid and thin, or tall and squishy? Foam pads (the most popular pad material) are available in a multitude of designs: they can be flat and smooth, or convoluted and dimply. There are also pads that feature wool, microfiber, felt… and even denim!

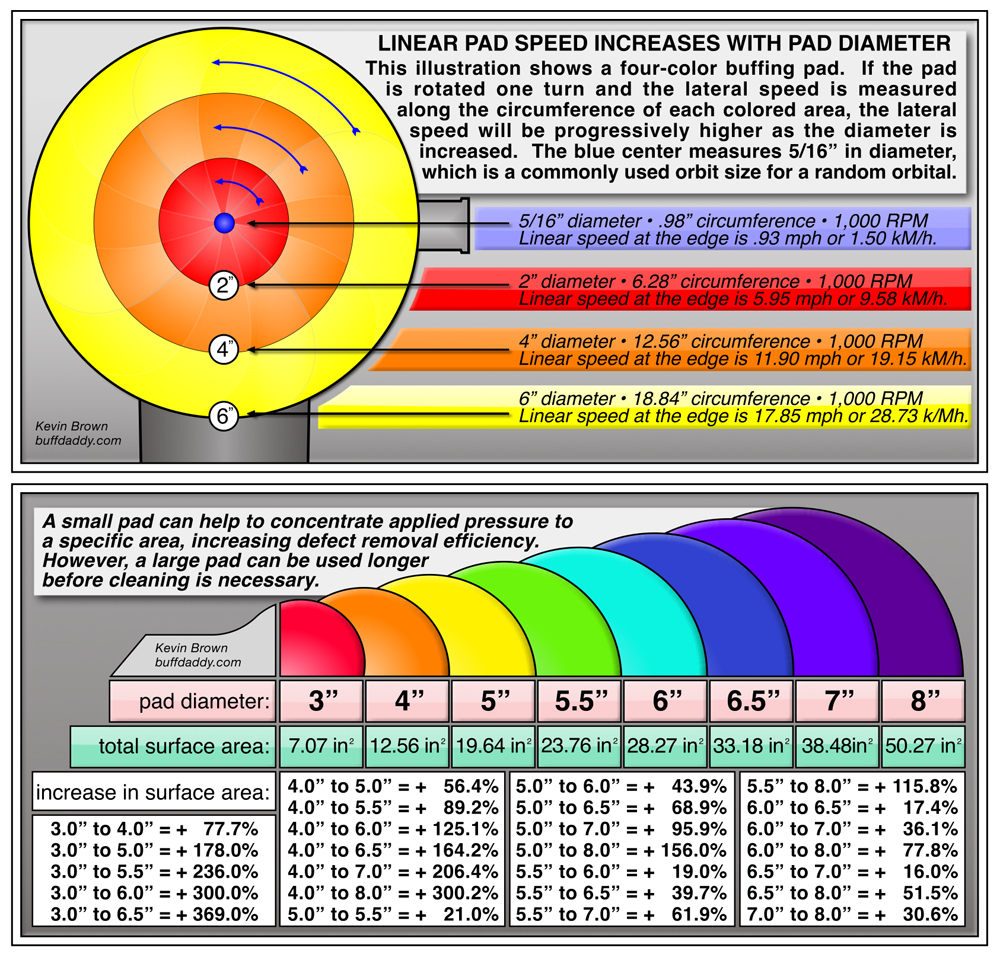

One of the most important parameters to consider when choosing a buffing pad is its diameter. Luckily, finding an appropriately-sized pad these days is easy, as most pad designs range in diameter from one-inch to nine-inch. As the chart illustrates, a pad will generate more speed along its edge as pad diameter increases. The chart also lists the total surface area of various pad diameters.

Small-Diameter Buffing Pads.

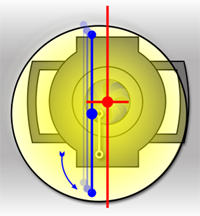

Small-diameter pads enable very specific polishing, and also make it easier to polish within confined areas. However, when used with a rotary polisher or drill, a higher speed setting may be needed, as the velocity along the outer edge of a small pad can be substantially slower than that of a large pad. The performance characteristics of a pad can also change depending upon pad diameter. This becomes especially obvious when using design-similar pads (with different diameters) that are installed onto the same machine.

Large-Diameter Buffing Pads.

Large-diameter pads can cover more ground than smaller pads, which can save time when polishing large areas of paint. By placing a small portion of the pad against the polishing surface, they can also be used strategically (seasoned users of the rotary polisher can confirm this to be true). When used with rotary machines, large pads deliver more speed along the edge of the pad. Depending upon the polishing task, this can be a benefit, or a drawback.

In addition to the most obvious benefit of using small or large pads (the ability to efficiently polish small or large areas), pad diameter impacts a multitude of other polishing parameters. Example: Small pads excel in concentrating machine motion and user-applied pressure to a specific area, but large pads can be used longer before cleaning is necessary.

Keep a Variety of Pad Diameters On-Hand.

Although being able to access the chart may not be a necessity in terms of building a highly efficient polishing system, having a variety of pad sizes on hand is. Regardless, the information listed within the chart is undoubtedly helpful, and further bolsters the premise that pad diameter is SO important to polishing performance.

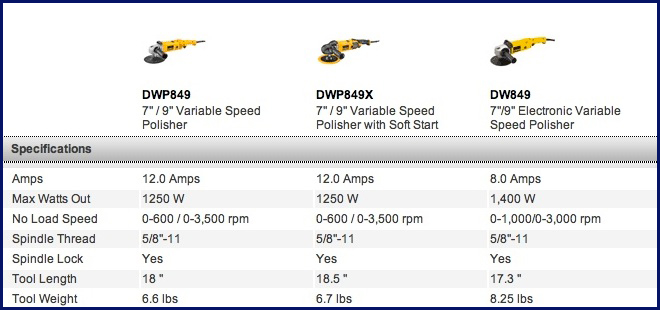

Detailers and paint polishing guys are dropping fat cash on machines these days. How much?

Detailers and paint polishing guys are dropping fat cash on machines these days. How much?

It sure is difficult to predict the “next big thing”. This statement holds true in the realm of paint polishing, too.

It sure is difficult to predict the “next big thing”. This statement holds true in the realm of paint polishing, too.

Meguiar’s® Online Photo

Meguiar’s® Online Photo As I scan the various detailing forums that we all enjoy, I think back to a simpler time, when forums did not exist. Simpler perhaps, but was it easier to learn about paint polishing, interior cleaning, and detailing in general?

As I scan the various detailing forums that we all enjoy, I think back to a simpler time, when forums did not exist. Simpler perhaps, but was it easier to learn about paint polishing, interior cleaning, and detailing in general? “Come again, Sonny? Now why would you go and say something as foolhardy as that? This little gem isn’t just

“Come again, Sonny? Now why would you go and say something as foolhardy as that? This little gem isn’t just  Ugh, head shake, and drat. I cannot think of any single thing that causes me to procrastinate more than paperwork does. The topic itself is quite interesting because although it seems contradictory, I really enjoy being organized!

Ugh, head shake, and drat. I cannot think of any single thing that causes me to procrastinate more than paperwork does. The topic itself is quite interesting because although it seems contradictory, I really enjoy being organized! As automotive paint is sanded, its surface becomes dull and non-reflective. This can strike terror into the minds of even the most experienced paint polishers among us. After all, these guys realize how difficult it can be to eliminate scratches, etch marks, and other below surface defects. Why would anyone in their right mind want to create more scratches atop the paint surface?!

As automotive paint is sanded, its surface becomes dull and non-reflective. This can strike terror into the minds of even the most experienced paint polishers among us. After all, these guys realize how difficult it can be to eliminate scratches, etch marks, and other below surface defects. Why would anyone in their right mind want to create more scratches atop the paint surface?!